views

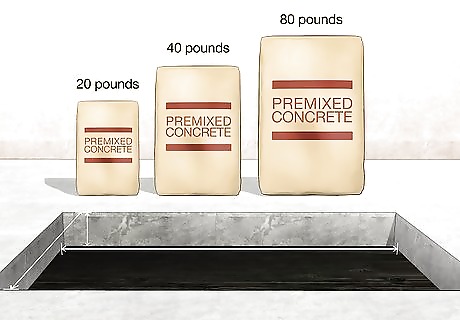

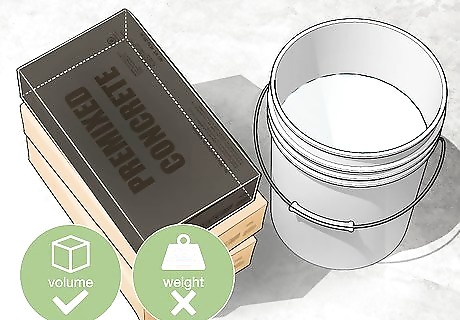

Figure out how much premixed concrete you will need for your project. Multiply the length times the width times the depth of the space you need to fill. This will tell you give a cubic size, or volume, of concrete that you need. Next, divide the volume (in cubic feet, meters, etc.) by the package yield of the material you are using. Typically, premixed concrete comes in 20, 40, and 80 pound bags, with the 80 pound bag yielding about 0.6 cubic foot of concrete.

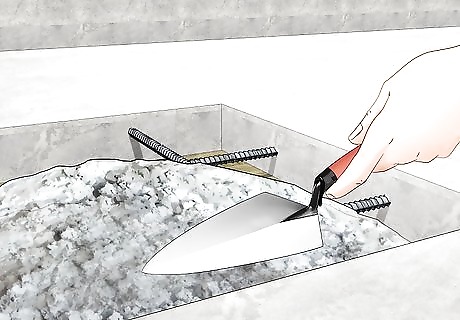

Prepare any forms you will need to hold the concrete, and grade and compact the soil or subgrade material. Place any reinforcing steel, and generally speaking, be ready for your concrete. Rebar is a good option if you're planning to pour concrete for a driveway.

Purchase the premixed product you have chosen to use. Here are a few examples of different mixtures commonly available: 3000 PSI (pounds per square inch) compressive strength, gravel, sand, and Portland cement mixture. This is a basic, inexpensive concrete suitable for most repairs, as well as for setting posts and poles. 4000 PSI mixture is for repairing or building structural concrete like sidewalks or driveways, where extra strength will increase the durability of the finished surface. 5000 PSI quick-setting concrete is a very strong mixture with a higher ratio of Portland cement to fine and coarse aggregates, typically used where quick-setting is desirable and higher strength may be needed. Sand mix contains no gravel or stone (coarse aggregate) and is used for grouting or topping, where a smoother surface is desired. Other mixes include premixed mortars, non-metallic non-shrink grouts and high-strength early (high early) concrete. These are specialty mixes for specific purposes not covered in this article.

Gather the materials you will need to complete your project. See "Things You'll Need" below for a complete list, but these will include your dry concrete mix, clean water, a shovel, and a container for mixing.

Open a bag of your concrete mix and pour it into your mixing container. Wheelbarrows (as in the pictures) are ideal for mixing small quantities of concrete. Avoid spilling the dry material on finished surfaces or lawn grasses, and keep upwind if possible to avoid breathing dust from this product.

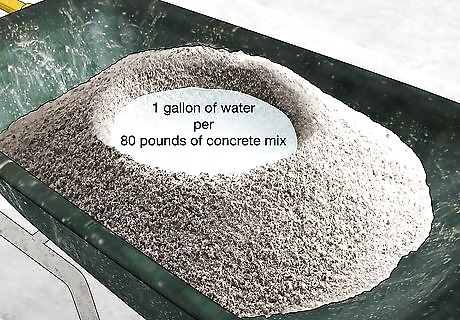

Make a small depression or hole in the dry material in the center of the container, using a shovel or mixing hoe. This will act as a reservoir for the water you add. Pour one gallon of water for each 80 pounds of dry mix into the depression. Don't worry about overflow or splashing, because all the container's contents must be mixed completely before the concrete is used.

Alternatively, when mixing concrete in a wheelbarrow, the water is added first and dry mix introduced after. The Portland cement, the key ingredient in concrete, is introduced to standing water, initiating hydration, not the reverse. Makes mixing with a shovel simpler and easier. Just the action of pouring mix in the water commences the hydration process without lifting a shovel. The trick is how much water per bag to add.

The water/concrete ratio is determined by the volume of Portland cement in the bag, not bag gross weight. The ratio is usually 1 gallon (3.8 L) per 80lb bag. But 1/5th of a 5 gallon (18.9 L). pail is hard to mix with 80lb of Portland cement, aggregate and admixture by hand shovel in a wheelbarrow. In revolving cement mixers, this is easy. With a shovel you end bulldozing through semi-rigid stubborn admixture that doesn't want to move. One way is to start by pouring two gallons in the barrow, dump the first bag in, mix completely into slurry, then add bag number two, assuming physically strong enough to maneuver the resultant weight. If not, pour a half 80lb bag into 1 gallon (3.8 L), mix thoroughly, then add the remainder, mixing thoroughly.

When mixing with the shovel, as funny or odd as may seem, the shovel is paddled through the mix just like canoeing. Plunging the shovel in the mix atop the water at the barrow's rounded front and paddling backward, scooping cement and carrying it back and dumping in the front to come in contact with water. All the shoveling is to bring the concrete mix in contact with water for the water and cement chemical interaction to do the rest. Repeating the paddling step over and over, as many times as it takes, until every speck of mix contacts water (usually about two to three minutes steady Eddie), as in cannot find any dry mix hiding along the bottom, sides or anywhere. You know it's fully mixed when you can grab a handful that won't keep its form after squeezed into a ball but yet isn't soupy. If forms a ball = too dry. If runs = too much water. The proper mixture for strongest concrete resides between dry and runny and ascertained by experience. The strongest is 0.45 water unit per Portland cement unit.

Stir the material and water, using a shovel or mixing hoe, so all the material is wet. Add additional water until the concrete is as plastic as you want it to be for your project. You should avoid making the concrete too thin, or soupy, as excess water will weaken the finished concrete, and will also allow the aggregates to separate out of the mix.

Continue mixing for a minute or two to completely mix the water into the concrete mixture. Concrete hardens through the process of hydration, so continuing to mix the material will insure the reaction will occur completely.

Place your concrete into your form, smoothing the surface with a shovel or other tool so any additional concrete you need to finish the job can be easily estimated.

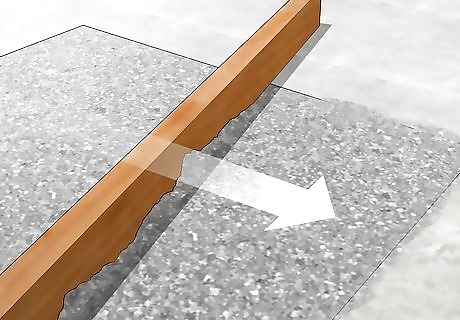

Float your concrete after it is placed and rodded off with a straight-edge or screed board. You may want to pat the concrete with your finishing tool to compact the material, removing any voids or air pockets which have formed as you placed it.

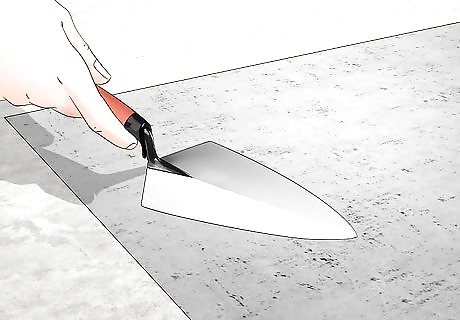

Finish the concrete according to your own requirements or the requirements of the project design.

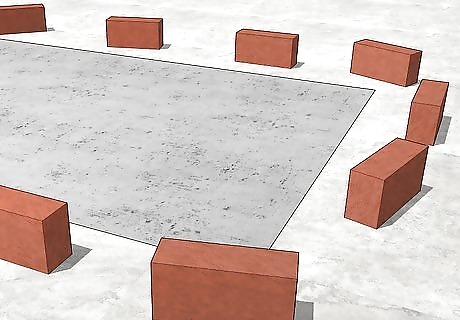

Barricade the area around the concrete to prevent passersby from stepping into it (which could ruin your finished project) and allow it to set and cure. Clean and put away your tools, clean up the area, and remove the empty bags when you are finished.

The technique to properly cure horizontal poured concrete, so will set over time to maximum strength and integrity, is to prevent the water added and mixed with the concrete in the barrow from evaporating away from the newly poured and troweled slab or other surface. .

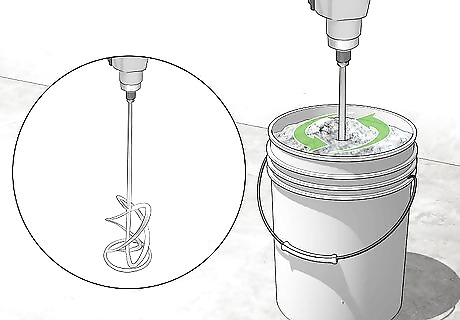

An alternative to mixing with a shovel and wheelbarrow is to mix in a standard five gallon bucked using a mixing drill with a "whip" attachment. This is best suited for mortar mixes but works with concrete mixes also. Fill a buck just less than 1/3 with water and add an entire 30kg bag of prepackaged concrete and mix.

Comments

0 comment