views

Checking the Motor with a Multimeter

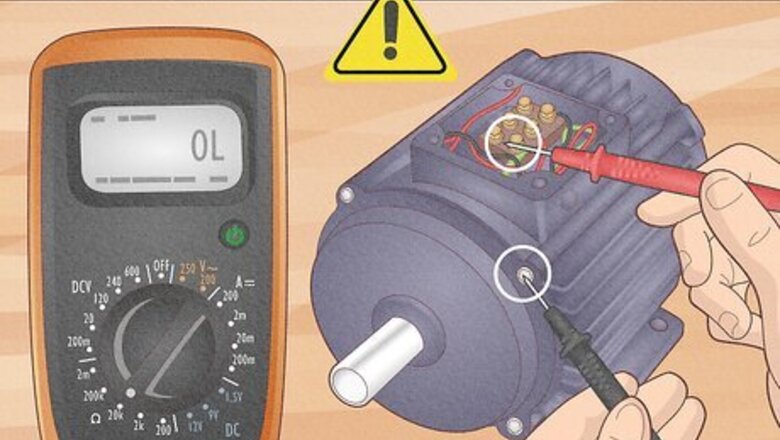

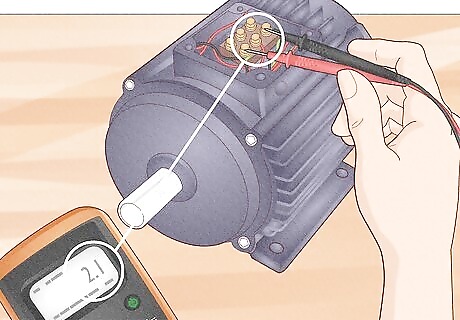

Confirm the motor is grounded before doing anything else. Many electric motors can run up to 240-480 volts, which is strong enough to potentially stop your heart. If the motor is not grounded, it is not safe to test. Confirm the motor is grounded using the following steps: Turn the motor off. Set your multimeter to continuity mode. This is often the same as the resistance mode (Ω). Press the negative (black) lead on any unpainted metal component that is on the motor’s housing and is not supposed to have a current. Holding the negative lead in place, press the positive (red) lead against each of the battery terminals. Warning: If you get a reading other than infinitive (I) or overloaded (OL), the motor is not grounded. Do not handle or work on the motor. Leave it be and contact a professional. Continue testing the terminals to ensure they’re reading I and/or OL. Test the case of the motor itself by pressing the red lead against any other unpainted metal. If you get all I/OL readings, the motor is grounded and you should be able to safely test the motor.

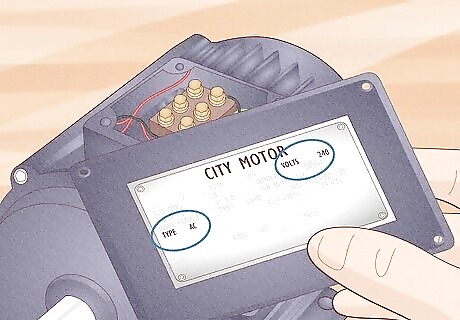

Inspect the label on the motor to find its configuration. Every electrical motor should have a label somewhere containing two key pieces of information: the type of current and the voltage of the motor. You must identify these pieces of information before testing your motor’s terminals for voltage. If you have an AC (alternating current) motor, use the AC voltage setting. Most of the time, this is the V with the squiggly line on it on your multimeter. If you have DC (direct current), use the DC voltage setting. This is the V with the solid line and dotted line on it. The voltage value you use to test on the multimeter must be identical (or higher) than the voltage of the motor you’re testing. So, if you have a

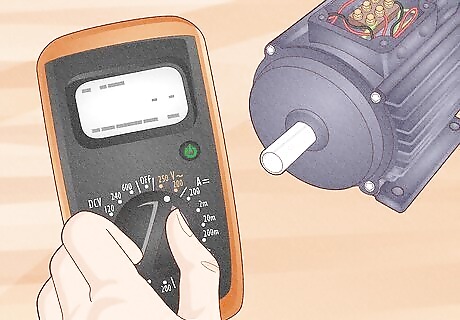

Set your multimeter to a voltage setting. A multimeter is similar to an ohmmeter, and either of them will work for this test. Plug your tool in and set it to a voltage in the DC or AC section depending on your motor. Pick a voltage that’s identical to the voltage your motor is designed for. If you do not know the voltage of the motor: Use the highest voltage setting available on the multimeter. However: if the readings you get match the highest voltage parameter (i.e. the multimeter is set for a max of 400 volts and you get a reading of 400 volts), the engine cannot be presumed safe to handle.

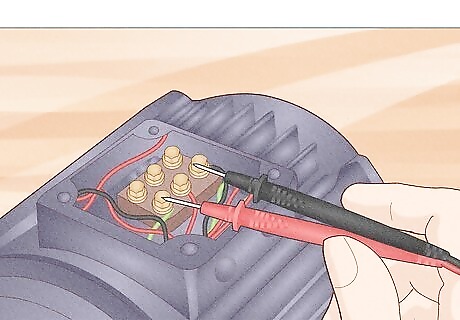

Press the probes to the positive and negative parts of the motor. Turn your electric motor off and make sure it’s unplugged. Electric motors come in different formats: some might have positive and negative probes, while others might use a grounding probe and motor leads. Connect the 2 wires from your tool onto your electric motor in one of the following ways: Locate a ground screw (often a green, hex head type) or any metal part of the frame (scrape away paint if needed to make good contact with metal) and press a test probe to this spot and the other test probe to each of the motor leads, one at a time. Find the positive (red) and negative (black) wires. Connect 1 probe from your tool to each of the wires.

Watch the readout for a resistance value. Ideally, the meter should barely move off the highest resistance indication, but should still show numbers indicating a resistance. Make sure your hands are not touching the metal probe tips, as doing so will cause the reading to be inaccurate. If the numbers do not move at all, it likely means that your electric motor has an electrical problem. Keep reading to diagnose what might be wrong. It depends on the type of motor you're testing, but most motors will have little resistance.

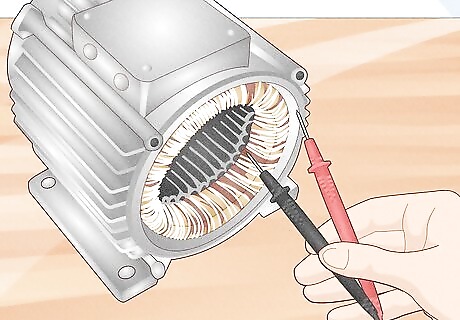

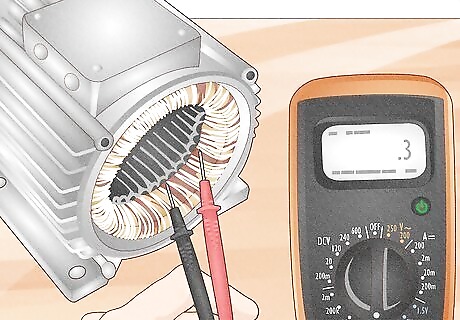

Check the windings for short circuiting to the frame. Most household appliance motors with a shorted winding will not run and will probably open the fuse or trip the circuit breaker instantly (600 volt systems are "ungrounded," so a 600 volt motor with a shorted winding may run and not trip a fuse or circuit breaker).

Check that the windings are not open or blown. Many simple "across the line" single-phase and 3-phase motors (used in household appliances and industry respectively) can be checked simply by changing the range of the ohm meter to the lowest offered (R X 1), zeroing the meter again, and measuring the resistance between the leads of the motor. In this case, consult the wiring diagram of the motor to be sure that the meter is measuring across each winding. Expect to see a very low value of resistance in ohms. Low, single digit resistance values are expected. Make sure your hands are not touching the metal probe tips, as doing so will cause the reading to be inaccurate. Values greater than this indicate a potential problem and values significantly greater than this indicate the winding has failed opened. A motor with high resistance will not run - or not run with speed control (as is the case when a 3-phase motor winding opens while running).

Inspecting the Bearings

Look at both ends of the motor. Many electric motor failures are caused by bearing failures. The bearings allow the shaft or rotor assembly to turn freely and smoothly in the frame. Bearings are located at both ends of the motor which are sometimes called "bell housings" or "end bells". There are several types of bearings used. 2 popular types are brass sleeve bearings and steel ball bearings. Many have fittings for lubrication while others are permanently lubricated or "maintenance free."

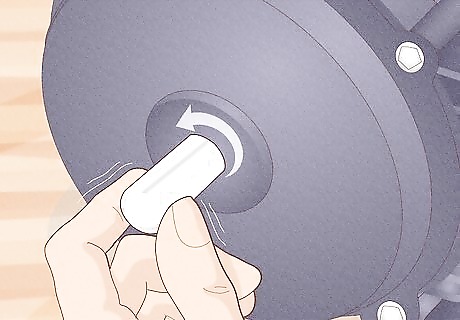

Spin the shaft or rotor. To perform a cursory check of the bearings, place the motor on a solid surface and place one hand on the top of the motor, spin the shaft/rotor with the other hand. Closely watch, feel, and listen for any indication of rubbing, scraping, or unevenness of the spinning rotor. The rotor should spin quietly, freely and evenly. If the bearings are not spinning freely, try lubricating them. They may be gummed up and unable to spin.

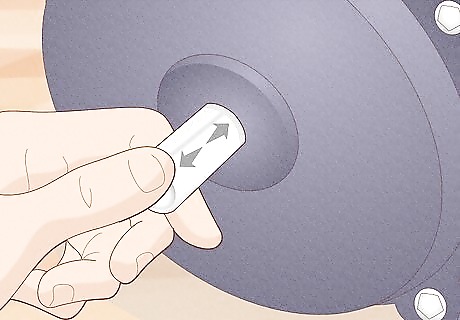

Push and pull the shaft in and out of the frame. A small amount of movement in and out (most household fractional horsepower types should be less than 1/8" or so) is permitted, but the closer to "none" the better. A motor that has bearing-related issues when run will be loud, overheat the bearings, and potentially fail catastrophically. Lubricate the bearings if they are stuck or jammed. Order correct replacement parts. "My pump's shot — but which one do I buy to replace it? The labeled anatomy sketches were clutch, mapping out bearings, switches, and wiring. Now I can use the proper terms when ordering so they send exactly the right motor." - Johan S. Diagnose pool pump issues with confidence. "When my pool pump started making weird noises and overheating, I panicked. Motors seem so complicated! But the easy instructions here walked me through testing windings and resistance step-by-step. Now I know how to check voltages and spin bearings, too. Understanding the basics empowers me to handle repairs myself instead of paying for a service call." - Mark W. Recall electrical knowledge through clear explanations. "I'll admit, I was never great with motors and capacitors — those classes were ages ago! So, when my pump failed, I needed guidance on troubleshooting. But this article broke everything down into simple steps an average Joe like me can follow. Using the multimeter diagrams revived enough long-lost skills that I'm back on track diagnosing issues." - Ren K. Grasp device repair through simplified instructions. "As a total non-techie, my pool pump motor seemed like a confusing jumble of parts. But the straightforward guidance here walked through testing functions piece by piece. Breaking repairs into bite-size steps gives me confidence I can figure this out, even without an engineering degree!" - Reza F. Have a story our readers should hear? Share it with 1 billion+ annual wikiHow users. Tell us your story here.

Troubleshooting Other Potential Problems

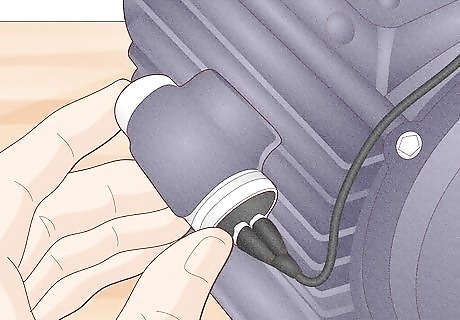

Test the start or run capacitor. Most capacitors are protected from damage by a metal cover on the exterior of the motor. Remove the cover to access the capacitor, then check it for leaking oil, bulges in the container, holes in the container, or smoke residue. Or, check the capacitor electrically with an ohmmeter. Place the test probes on the capacitor terminals, then make sure the resistance starts low and gradually increases. If it stays shorted or does not rise, there is probably an issue with the capacitor and may need to be replaced.

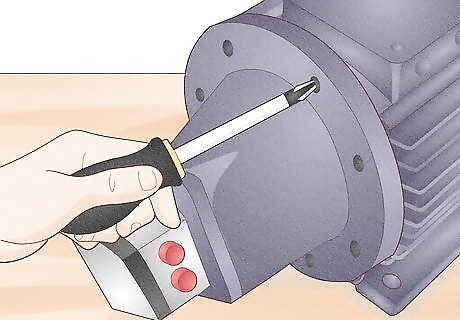

Inspect the rear bell housing of the motor. Some motors have centrifugal switches used to switch the start / run capacitor (or other windings) "in" and "out" of the circuit at a specific RPM. Check the switch contacts are not welded closed or are contaminated with dirt and grease that could prevent a good connection. Use a screwdriver to see if the switch mechanism and any spring can be operated freely.

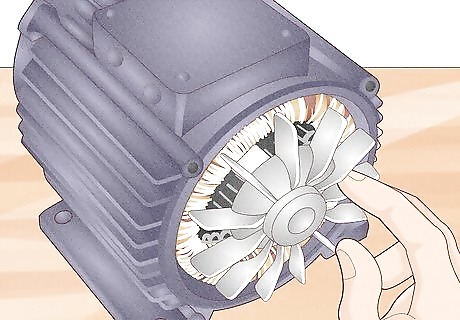

Look at the fan. A "TEFC" type motor is a "Totally Enclosed, Fan Cooled" type. The fan blades are behind a metal guard on the back of the motor. Make sure it is securely fastened to the frame and is not clogged with dirt and other debris. The openings in the rear metal guard need to have full and free air movement; otherwise, the motor will overheat and eventually fail.

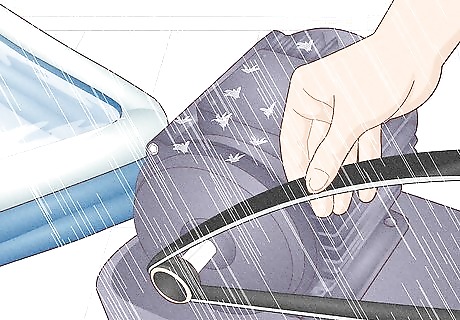

Choose the right motor for the expected conditions. Check that drip-proof motors are exposed to directed water spray or moisture, and that open motors aren't exposed to any water or moisture at all. Drip-proof motors can be installed in damp or wet locations, so long as they are installed in such a way that water (and other liquids) can not enter due to gravity and must not be subjected to a stream of water (or other liquids) directed at or in it. Open motors are, as the name implies, completely open. The ends of the motor have rather large openings and the windings in the stator windings are plainly visible. These motors should not have these openings blocked or restricted and should not be installed in wet, dirty or dusty areas. TEFC motors on the other hand, can be used in all the previously mentioned areas but must not be submerged unless designed specifically for the purpose.

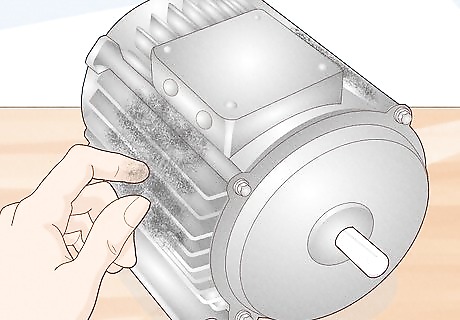

Inspect the outside of the motor. If the motor has any of the following issues on the outside, they may be problems that can shorten the life of the motor because of previous overloading, wrong application, or both. Look for: Broken mounting holes or feet Darkened paint in the middle of the motor (indicating excessive heat) Evidence of dirt and other foreign matter having been pulled into the motor windings through openings in the housing

Comments

0 comment