views

Finding and Evaluating Your Belt

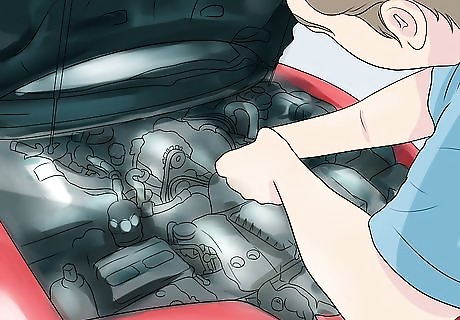

Park your car in a well lit place. This will make it easier to work under the hood. You can also use a drop light or other supplemental lighting if you deem it necessary.

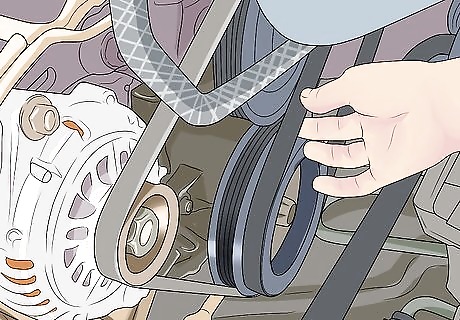

Locate the belt in question. Most belts will be found on the side of the engine block. Serpentine belts are easily identified because they weave through several pulleys. V-belts are looped around two pulleys and there are two or more belts overlapping at a point, forming a V-shape. You should replace the belt: if it is frayed or tearing. if it has cracks or missing chunks. if the belt has coolant or oil on it. These conditions make the belt incapable of properly running its components, which can lead to major problems for your engine. If for any reason you cannot locate an accessory belt or gain easy access to it then you should take your vehicle to professional.

Removing the Old Belt

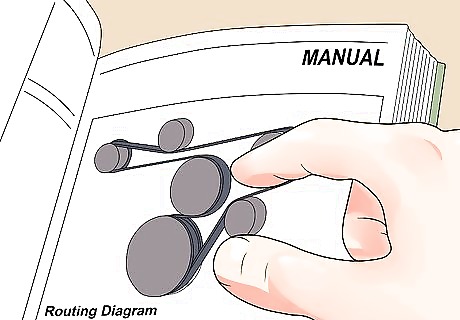

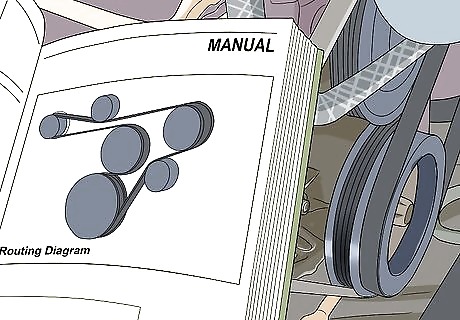

Locate a routing diagram. This can usually be found posted underneath the hood of your car or in your service manual for serpentine belts (S-belts). If you drive a much older car, you may have a multi-belt design (V-belt). Either way, if you cannot find a routing diagram you should take a picture or draw one before removing the belt(s). Be sure to make note of whether the grooved side or flat side of the belt makes contact with each pulley. It is important not to put the new belt on backwards.

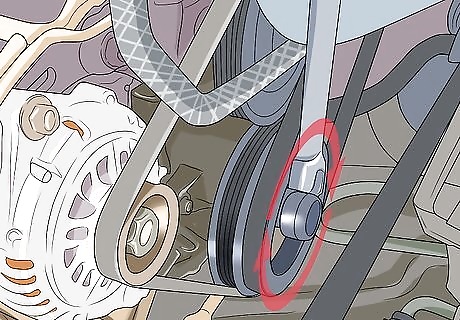

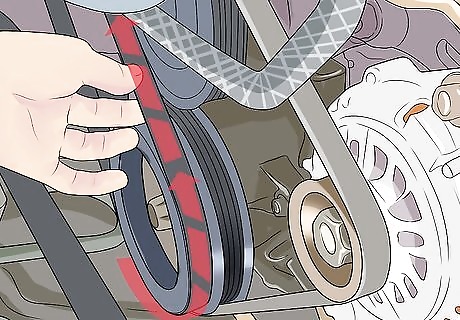

Release the tension on the belt. There are a few things to remember when releasing tension on a belt. For serpentine belts this is done by compressing the spring loaded tensioner. The tensioner is just another pulley that the belt runs over, but only serves to keep tension on the belt and does not power any accessories. Some tensioners can be compressed by turning them with simple hand tools such as a wrench, and others may require a special tool. Usually twisting the pulley clockwise will compress the spring. V-belts do not have an automatic tensioner. They can be removed by adjusting the position of one of their pulleys to release tension. To loosen a pulley, turn it with a wrench or specialized tool. By convention, counter-clockwise will loosen the pulley.

Remove the belt. Once tension is released, the belt should slide off of the other pulleys easily.

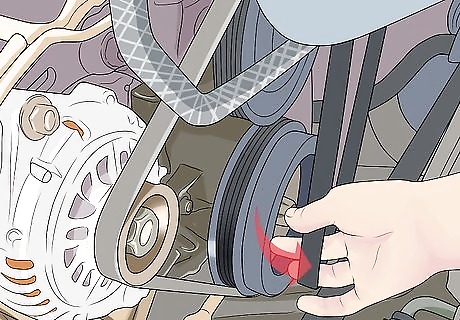

Check the pulleys. One reason for a damaged belt is a malfunctioning pulley. You should check the tensioner and all pulleys that the belt contacts. Older tensioners might cause a slip in the belt. If one wobbles or does not spin freely then you may need to replace it.Change an Automotive Belt Step 6 Version 4.jpg

Running the New Belt

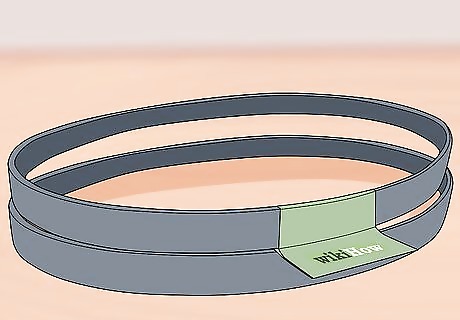

Compare the new belt to the original. Since these belts need to fit exactly right, the new belt should be the same length and width as the original. The only difference should be general wear on the old belt. The best way to insure a perfect match is to compare part numbers.

Run the new belt. You should use your routing diagram from above to make sure that the belt is run properly. Pulleys with grooves are intended to meet the grooved side of the belt, but some flat pulleys are meant to be driven by the flat backside of the belt. When you are done, the belt should weave through the pulleys contacting each pulley only once.

Tighten the belt. You want to make sure that your belt has the proper amount of tension on it. Older tensioners might cause a slip in the belt.Change an Automotive Belt Step 9 Version 4.jpg For serpentine belts use the same tool you used above to compress the tensioner and turn it in the opposite direction (counter-clockwise) until the spring releases. If you are working with a V-belt design then you will need to tension the belt manually. #*Find the middle of the belt's longest stretch. Move that point from side to side and the belt should have ⁄2 inch (1.3 cm) of movement in either direction. Any less and the belt is too tight, any more and it is too loose. Check your vehicle manual for more information. If in doubt, consult a mechanic.

Double Check Your Work

Step back and look at the belt. Does it match the routing diagram exactly and look like the belt you took off? If the belt does not fit properly or is not installed correctly it could damage several important components of your car such as the water pump, alternator, etc.

Start your car. If possible it is best to have a friend start your car while you watch the belt. You want to be sure that it is running smoothly with no squealing or slipping. Be careful to keep your hair and clothing away from any moving parts under the hood of your vehicle.

Troubleshoot any problems. If you notice anything wrong such as slack in the belt or squealing, consult your routing diagram again. You may need to re-run the belt or make sure that it is properly tensioned. You should also check again to be sure all accessory pulleys are turning freely, including the tensioner. If you cannot diagnose the problem you should take your vehicle to a professional.

Comments

0 comment