views

Opening the Dispenser

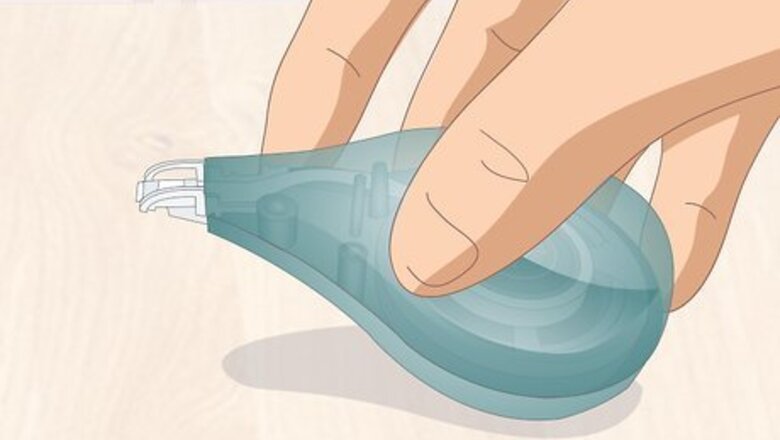

Place the dispenser face-up in front of you. Set the plastic white out tape dispenser on a flat surface like a table or a desk. Keep it face-up so the logo is facing you and the tape side is facing down. Work on a clean surface so the tape doesn’t stick to anything.

Wedge a flathead screwdriver in between the crack where the 2 halves connect. The dispenser consists of 2 connected halves and you can see the line where they connect running through the center of the narrow side. Take a screwdriver and gently insert it into the crack. Don’t force the crack apart or you could break it.Tip: Use a butter knife or even a coin to help separate the 2 halves if you don’t have a screwdriver that fits.

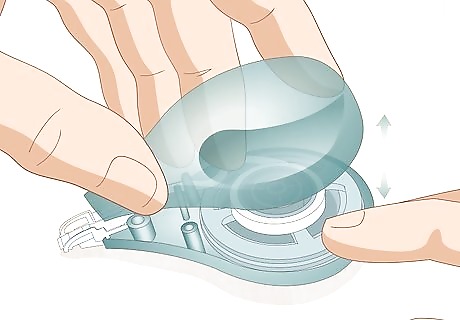

Apply gentle pressure to separate the 2 halves of the dispenser. Once you’ve got the screwdriver wedged into the crack, start to apply gentle, downward pressure. Continue to slowly build up the pressure until you hear a “snap” that indicates that they’re separating. Be careful not to chip or crack the edges where the 2 halves connect with the screwdriver.

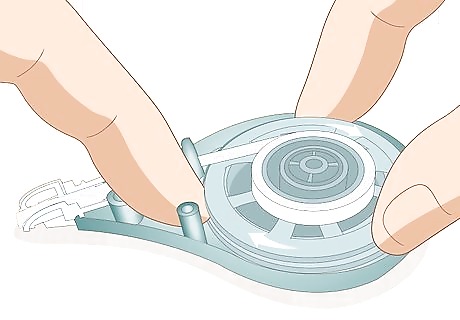

Use your fingers to pull the 2 halves apart. When you hear and feel the halves of the dispenser snap apart, remove the screwdriver and apply pressure with the tips of your fingers to finish separating them. You’ll see the wheel of the white out tape attached to 1 half of the dispenser. Don’t snap or bend the dispenser to open it or you could break it.

Tightening the Slack

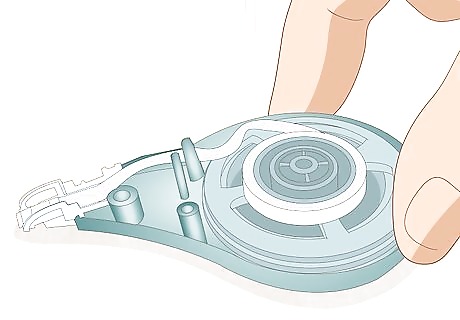

Lay the half of the dispenser on its side with the tape wheel facing up. Once you’ve opened the plastic case, lay the half that contains the tape wheel down so it’s easier to work on. Keep the tape dispenser side facing up towards you.Tip: Keep the other half of the dispenser nearby so you don’t lose it.

Use your fingertip to immobilize the bottom of the larger wheel. Hold the half of the dispenser with the tape wheel still with one hand. Insert the index finger of your other hand between the spools to hold the larger wheel in place. Holding the wheel in place will help you rewind the spool of tape. You don’t need to apply much pressure to keep the wheel still.

Rotate the wheel clockwise to start tightening the tape. While you’re keeping the larger wheel immobile, release enough pressure to allow you to rotate the wheel clockwise. The white out tape will start to re-spool on the wheel and the slack will tighten up. Continue to turn the wheel until all of the slack is gone, but don’t tighten it so much that it snaps the tape.

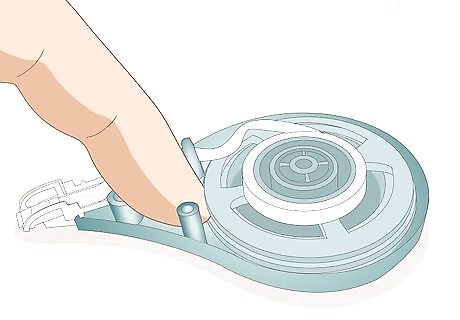

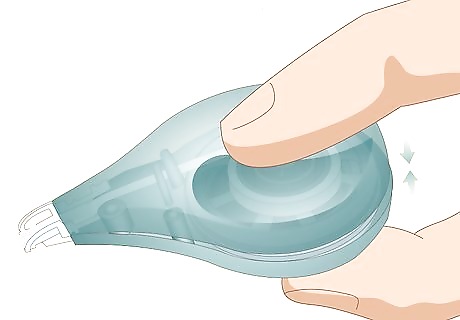

Reconnect the 2 halves of the plastic cover of the dispenser. After you’ve taken the slack out of the white out tape and the spool is re-wound, take the other half of the dispenser and line up the edges of the 2 halves. Apply pressure with your hands until you hear them snap back together. You shouldn’t have to apply too much force to reconnect the two halves. Be careful not to break the edges that line up on the halves of the dispenser.

Apply a small strip of white out on a piece of paper to test it. With the slack removed and the dispenser put back together, apply a small strip of the white out tape to a piece of paper. Use it as you normally would so you can test it to make sure it’s working properly. If the white out tape continues to function improperly or come unwound, you may need to replace the white out tape dispenser.

Comments

0 comment