views

- To fix a torn seam, thread a needle with thread that matches the garment’s color and snip away any loose threads or badly worn fabric around the tear.

- Flip your garment inside out and weave your threaded needle in and out of the fabric in a running stitch. Sew in a straight line parallel to the seam.

- Secure your seam with a double knot then snip the thread. Gently pull at the newly mended seam to ensure it’s secure.

Repairing the Seam by Hand

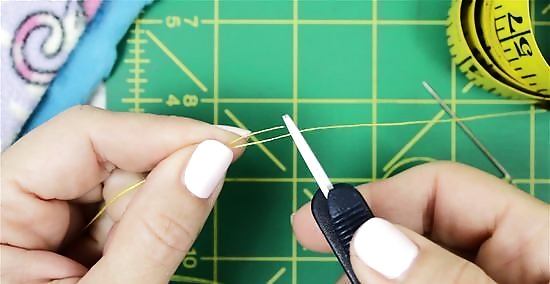

Thread a needle with thread that matches the garment. Loop the thread through the eye of your needle. If the edge of the thread is frayed or otherwise impaired, trim it back until the thread is smooth with a blunt edge. If necessary, wet the end of the thread before passing through the head of the needle. Choose a needle and thread according to the garment you’re repairing. Use a thin needle and thin thread with chiffon, lace, or silk fabric, or a thicker needle and heavier thread with denim or canvas. If you don’t have thick thread on hand for heavy-duty fabrics, loop two ends of your thin thread through the eye of the needle instead.

Cut the thread, leaving several inches of extra space. Use double the length of the busted seam and add another 1 to 2 inches (2.5 to 5 cm). While you may wind up with too much thread, it's better to have too much than too little, as you may be able to see where your stitch starts and stops in the middle of the torn area.

Practice a running stitch to repair your busted seam. A running stitch is a beginner-friendly option involving a single, straight line. Practice a running stitch on some scrap fabric before mending your garment. Poke your threaded needle up through the fabric, then back down right next to where you first came up. Pull the thread into your first stitch and poke your needle back up. Leave a space of about ⅛ inch (3.2 mm) from the previous stitch and repeat. For intermediate sewers, try different stitches that work well for varying fabrics and problems. For delicates, you may want to try a simple whip stitch, or for exposed seams that require a discreet repair, you may want to try a backstitch.

Flip the garment inside out and begin stitching ½ in (1.3 cm) from the seam. Prepare your stitch by knotting the thread to keep it secure. Slip your threaded needle through the fabric about ½ inch (1.3 cm) before the rip in the seam begins. Stitch only through sturdy fabric so the thread is secure. Stitch in a straight line along the seam to close the hole, staying at least ¼ inch (6 mm) away from the seam. Favor a tighter stitch rather than a loose one. Even though a loose stitch is faster and easier, you risk tearing your seam again.

Stitch slight past the tear a secure your seam with a double knot. Once you have reached the edge of the torn seam, keep sewing about another ½ inch (1.3 cm). Tie a firm knot in your thread to prevent further fraying and damage. If your knot is too loose, your newly repaired seam may begin to unravel, while a tight knot may cause snagging. Smooth the fabric to ensure there are no wrinkles or problems, then tie a knot to lie flush against the fabric. Tying the knot will be easier if you keep the needle intact and pull the needle through the loop you’ve made for your knot. This is especially true if you have only an inch or so of extra thread.

Test the result by gently pulling at the seam. Turning the fabric right-side-out, gently pull apart the area you’ve mended, ensuring there are no ripples, remaining holes, or snags. If you find a snag, use a seam ripper to remove your thread and start again. While you want to check to ensure your seam is solid, avoid yanking on the seam, as this can damage even the most well-constructed item of clothing.

Repairing With a Sewing Machine

Thread your bobbin and machine with thread that matches the garment. Choose the color that best suits your seam, whether visible or not. Although the color may not seem important initially, a dark or light thread will be immediately visible if your fabric is even a tiny bit sheer. Once your bobbin is set, follow your machine's user manual for instructions on how to thread the needle.

Use the running stitch setting on your sewing machine. New and old sewing machines come with a wide array of settings, ranging from the length of a stitch to the type of stitch being used. A running stitch remains to be a handy, simple way to repair torn or busted seams. However, you can consult your machine’s manufacturer’s booklet or instruction manual to determine which setting is best for your fabric. For knits or elastic waistbands, opt for a stretch stitch which can move with stretchy fabric materials. For tears in difficult places, like the armhole (also known as the armscye), use a triple straight stitch.

Pin your seam in place if it's large or unruly. It may help to use sewing pins or clips to temporarily hold seams together before stitching. Try forked pins to be able to see your pin on both sides of the seam, or small applique pins for curved seams that require many pins to hold their shape.

Place the fabric under the foot so the needle is ½ in (1.3 cm) from the tear. Fold the fabric in half so the machine can stitch both layers of the fabric together. If possible, line the existing thread up with the machine’s needle to keep the appearance of a uniform seam. Aim to keep your stitch about ⅛ inch (3.2 mm) from the seam (making sure you're only sewing through intact, sturdy fabric). Use the guidelines on your machine's plate to help you position the fabric in line with the needle.

Slowly feed your fabric through the machine. Gently press down on the machine’s pedal, feeding your fabric through the machine carefully. Again, though you may think it is best to get the job done quickly, the needle could snag on the fabric if it's passed through too quickly. Take your time. Remove your pins as you go, ensuring they do not pass beneath the machine’s needle. Although it could skip over the pin, you risk breaking the needle when it hits the pin.

Run back over the stitch's final ½ inch (1.3 cm). Once you have reached the end of the tear, pause the needle and put the machine in reverse. Go back over your fabric to close the thread loop. This process is also referred to as backstitching. Once you have done that, lift the foot and remove the fabric. ½ an inch (1.3 cm) is more than enough space. Going over any more of the fabric may accidentally rip up your repaired stitches.

Remove excess thread to prevent fraying. Snip the thread from the bobbin and needle, and trim any excess fabric or thread from the newly mended area. If there are frayed edges, be sure to trim those, too, as leaving a frayed edge behind could result in additional fraying.

Comments

0 comment