views

Work Area

Wear fire-retardant clothing and heavy leather-soled boots. Do not wear loose-fitting clothes, clothes made from flammable synthetic materials, or clothing with frayed or torn edges that may ignite more easily than tightly-woven, clean-hemmed garments. Fire-retardant clothing is recommended but, if that isn’t available, wear close-fitting cotton clothes. Nylon and most other common synthetic clothes will rapidly burn if caught on fire! Sturdy, leather-soled work boots are recommended. Hot pieces of metal, called slag, can easily burn through rubber-soled shoes. Laced boots are preferable since slag can drop into the top of pull-on boots, like engineer's boots and cowboy boots. You should also have a set of cutting goggles and heavy leather gloves.

Have a fire extinguisher on hand. For most projects, a compressed air and water extinguisher will work, but if oil, plastics, or other combustible materials are around, an "ABC" extinguisher is recommended. It’s also a good idea to have another person standing nearby who can alert you if something catches fire. Flying slag can easily cause a fire in your workspace, so test your fire extinguisher to ensure it’s in good working order before you start cutting.

Ensure your workspace is free of flammable materials. Working on bare earth or a concrete slab is highly recommended since sparks are going to fly many feet from the cutting location. Dry material like paper, sawdust, cardboard, and dried plant foliage or grass can be ignited from 15 feet (4.6 m) or further. Do not allow the flame to contact concrete, especially fresh concrete, as it may cause it to expand and crack violently, sending small bits of concrete flying.

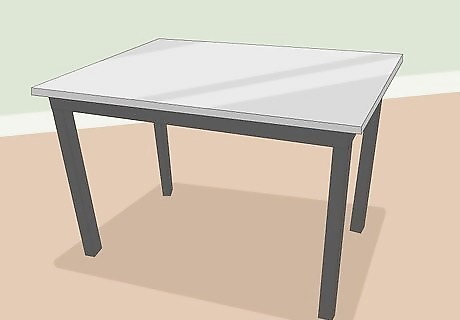

Set up the project on steel supports at a comfortable working height. A steel table is ideal since you can brace yourself to steady the torch. Never use a surface that is flammable, like a wooden table, or one that has had flammable materials spilled on it. Also, beware of material that has metallic oxide coatings, such as lead paint, chromate primers, and zinc plating, since inhaling the fumes from these can be toxic.

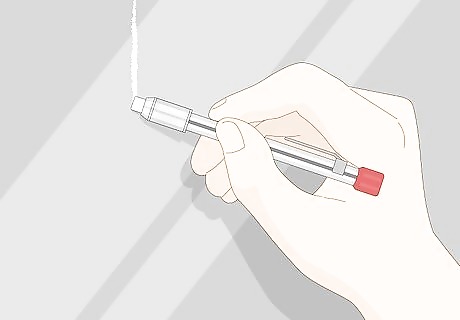

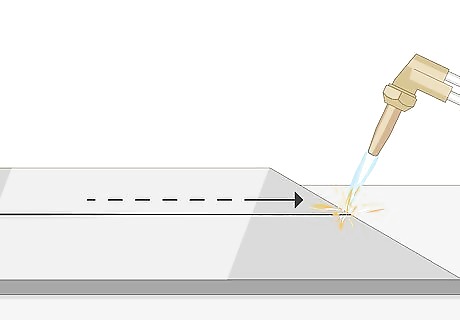

Mark your cuts with a soapstone marker. If you need a more precise cut, measure a little extra space so you can grind your cut. You may use a permanent marker if a soapstone is not available, but the mark will tend to disappear just ahead of the torch flame. For very precise cuts, you may get better results by using a specialized jig to etch the line into your work surface.

Setup

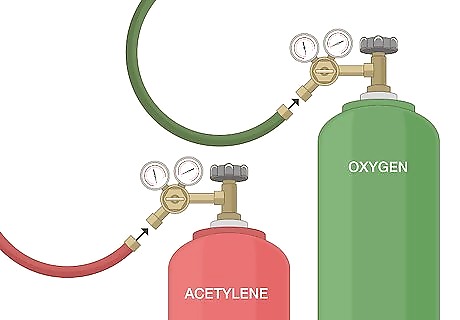

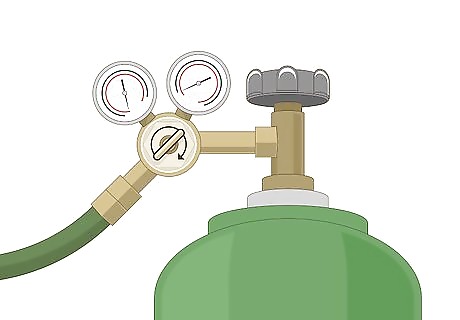

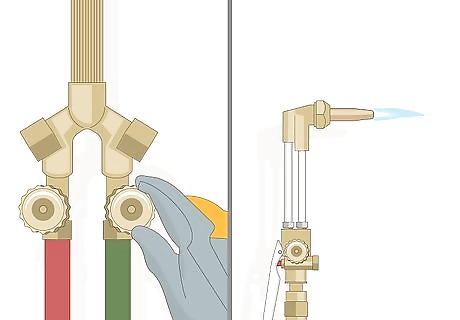

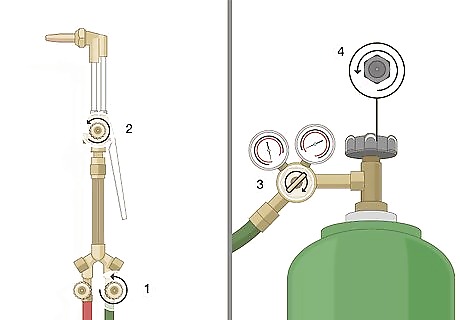

Hook up the gauges to the appropriate tanks. The hoses from your torch should attach to the nozzles on the oxygen and acetylene tanks. Typically, oxygen tanks and hoses are green, and acetylene hoses are red. The hoses are usually paired together, and the ends are separated so they can attach to their respective tanks. The acetylene hose will have reversed threads and a male fitting to make it easier to tell them apart. Since the fittings are made of brass and can easily be damaged, tighten them with an appropriately-sized wrench.

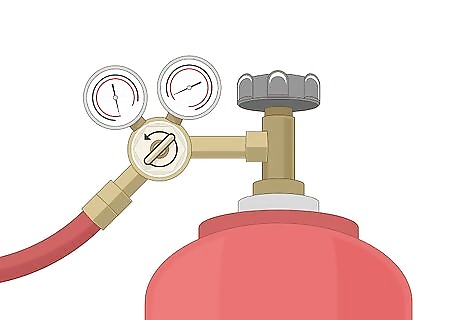

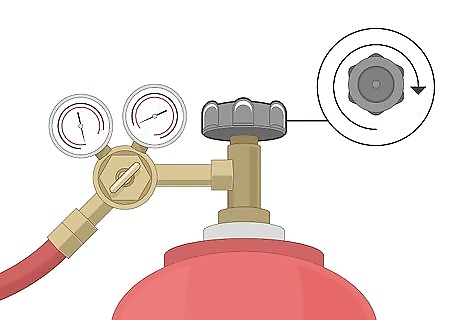

Make sure the acetylene regulator is turned off. To check that the regulator is completely off, back the tee handle out a few turns. This handle will be on top of the tank right next to the regulator valve. This will help ensure that you have complete control over the acetylene gas pressure. At higher than 15 psi (100 kPa), acetylene becomes unstable and may spontaneously ignite or explode.

Open the gas valve on top of the acetylene tank with one turn of the wrist. Again, it’s extremely important to maintain control over the flow of the acetylene, so you want to open the gas valve just enough to allow a constant, steady flow of the gas. Opening the tank more than a single turn could lead the gas to become unstable, and it will be harder to turn off in the case of an emergency.

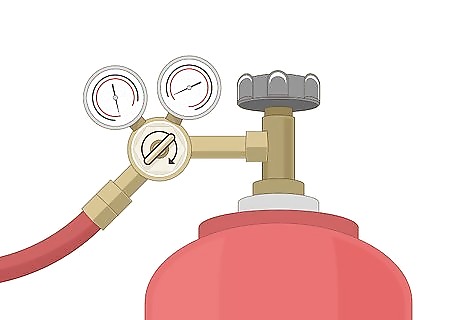

Open the regulator valve by turning the tee handle clockwise. This is the same handle that you closed before opening the gas valve. You should open this very slowly, and you should constantly monitor the low-pressure gauge while you’re opening the valve. Open it only until the pressure indicated is between 5–8 psi (34–55 kPa).

Open the gas valve on the torch handle to vent it. To vent the atmosphere from the acetylene hose, open the gas valve on the cutting torch handle until you hear gas escaping, then observe the low-pressure gauge to see if the pressure remains steady during flow and ensure that you have this regulator set correctly. Close the acetylene valve on the torch once you are sure the pressure is regulated.

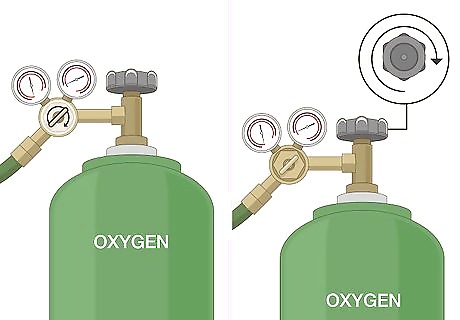

Turn the oxygen regulator off, then open the main oxygen tank all the way. In the same way that you closed the acetylene regulator, back the oxygen regulator gauge out a few turns. Once you’ve done that, turn the handle on the main oxygen tank so it’s all the way open. The setup on top of the oxygen tank will be similar to that on the acetylene tank. The oxygen valve is a double-seated valve. When you open it, be sure to turn the handle so the valve is all the way open. Otherwise, the oxygen will leak out around the valve-stem O-ring.

Open the oxygen regulator valve slowly. Just like with the acetylene regulator, you’ll turn the tee handle very slowly, watching the low-pressure gauge as you do so until the pressure reads between 25–40 psi (170–280 kPa).

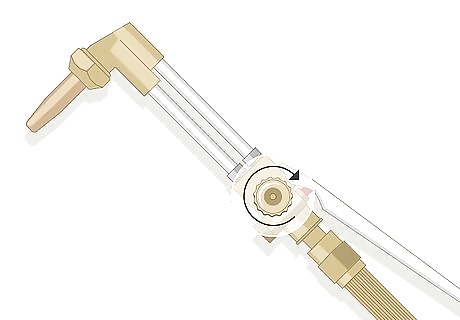

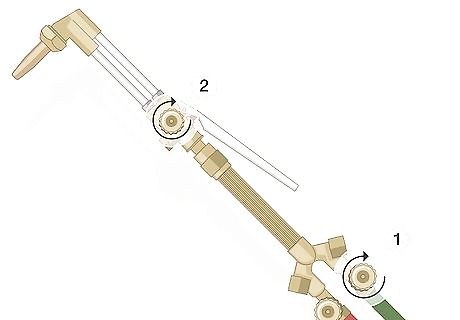

Open and close the oxygen valve on the torch to vent the atmosphere. There are 2 valves on the oxygen side of the cutting torch assembly. To begin with, open the valve closest to the hose several turns to ensure sufficient oxygen is available for both functions. Next, open the forward valve slightly until the hose is purged (about 3-5 seconds for a 25 feet (7.6 m) hose), then close the forward valve. The valve near the hose connections will control the flow of oxygen to the mixing chamber for the combustion, so no oxygen should vent from the torch tip until either the cutting lever is depressed or the valve further up the torch is opened.

Cutting

Put your gloves, apron and goggles on before lighting the torch. When it comes to working with an acetylene-oxygen torch, you can never be too careful. Put on all of your safety equipment and check your work area one more time for combustible materials.

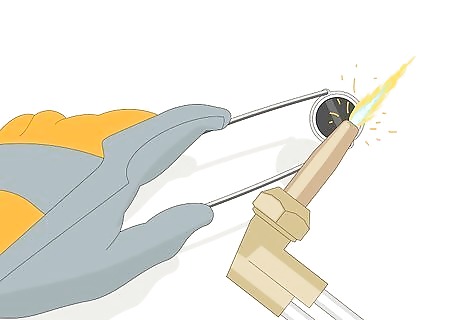

Light the torch with a striker. Open the acetylene valve again, allowing the oxygen remaining in the mixing chamber to purge for a few seconds, then shut the valve until you can barely hear gas escaping. Hold your striker in front of the torch tip and squeeze the handle. A small yellow flame should appear at the tip when the sparks from the striker ignite the acetylene. Using matches or a cigarette lighter is very dangerous. A striker is a tool made especially for igniting torches, and using one reduces the risk of serious injuries.

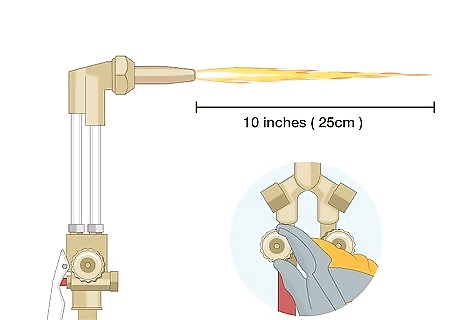

Adjust the acetylene valve until the flame is about 10 in (25 cm) long. Make sure the flame begins at the torch tip. If the flow of acetylene is too strong, the flame will “jump”, or be blown away from the tip. This can lead to an unpredictable cutting edge, which may increase your risk of fire or injury.

Turn the forward oxygen valve on slowly. The flame color will turn from yellow to light blue with a white center as sufficient oxygen is supplied to completely combust the acetylene. Increase the oxygen slowly until the inner blue flame begins to shrink back toward the tip.

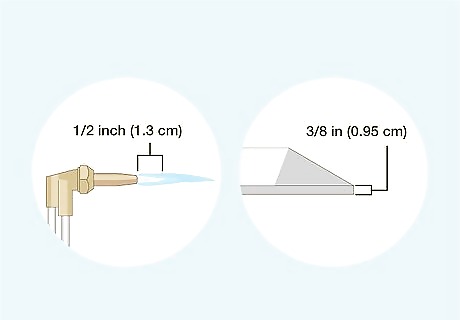

Open the oxygen valve more to increase the flame size. The length of the inner flame should be just over the thickness of the steel you are intending to cut. For instance, a ⁄2 in (1.3 cm) inner flame is about right for a ⁄8 in (0.95 cm) cold-rolled plate or mild steel. If you hear a blowing noise, or the blue flame seems erratic and feathery, there is probably too much oxygen at the flame. Reduce it until the flame is stable and the inner flame is a clean cone shape.

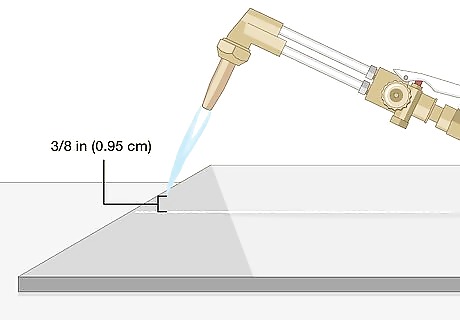

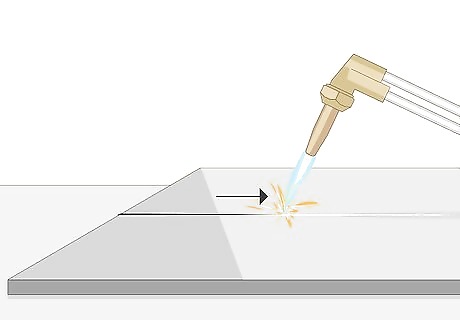

Bring the tip of the inner flame near the surface you are going to cut. The flame doesn’t have to sit directly on the surface to cut it. You will need to heat the steel with this flame until a molten pool of metal forms and luminesces at this location. Keep the tip of the flame steady and about ⁄8 in (0.95 cm) from the metal's surface to concentrate the heat in one location. For room-temperature ⁄4 in (0.64 cm) plate steel, this should take about 45 seconds. However, it will take longer for heavier material or material at low temperatures.

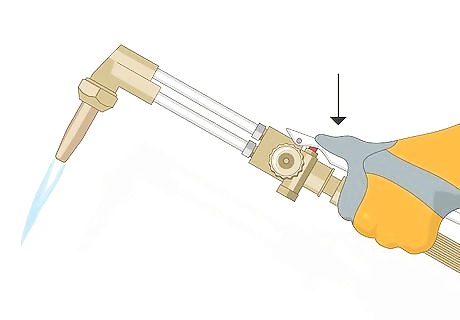

Push the cutting valve handle down slowly to release the oxygen jet. This will ignite the molten steel. If a violent reaction instantly starts, the steel has ignited, and you can gradually increase pressure until the jet is cutting completely through the metal. If no reaction occurs, the metal is not hot enough to ignite. In this case, release the oxygen handle release and continue to allow the flame to heat the metal more.

Begin moving the torch tip slowly along the line of your cut. Once the jet is cutting through the steel, start moving the torch along the line you drew. You should observe that almost all of the sparks and molten slag are being blown out the back or bottom of your cut. If this flow of superheated material slows or backs up, slow your forward speed or stop and let the metal heat more. It’s better to cut too slowly than to try to cut too quickly.

Continue cutting until you have parted the metal or finished the cut. Make sure the slag and any droplets of heated metal do not get underfoot. Even sturdy boot soles will burn through if you find yourself standing on a large piece.

Turn off the torch in the reverse order of how you turned it on. First, turn off the torch valve, then turn off the oxygen. Next, turn off the cylinder valves on the oxygen tanks and back out the regulator pressure screw. Repeat this for the acetylene tank. Some models may instruct you to turn off the oxygen before turning off the torch valve. In this case, always defer to the manufacturer's instructions.

Cool the workpiece with plenty of water. However, you should be aware that dipping a superheated piece of steel into a bucket or stream of cold water will create an instantaneous cloud of very hot steam. You could also allow it to cool naturally if you aren’t in a hurry. If you're using quench- or temper-type steels, allow the steel to cool naturally, as water could cause them to warp.

Comments

0 comment