views

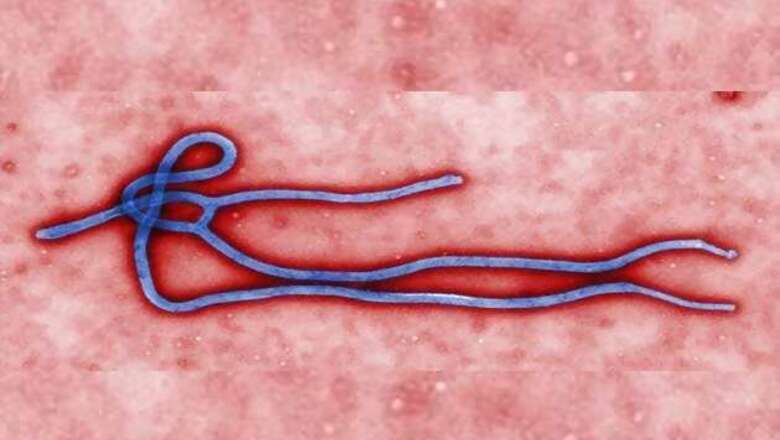

New York: All three US facilities established to quickly make vaccines and therapeutics in the event of a major public health threat say they are standing by to support any US government effort to scale up a treatment for Ebola.

The facilities, called Centers for Innovation in Advanced Development and Manufacturing (ADM), were set up by the US Department of Health and Human Services in partnership with private industry, to respond to pandemics or chemical, biological, radiological, or nuclear threats.

They have the expertise to quickly switch production lines to manufacture, for example, a smallpox vaccine if that scourge were to re-emerge, or an anthrax vaccine, and other life-saving compounds against both natural outbreaks and bioterrorism.

"They know our number and they can call us 24 hours a day," said Brett Giroir, chief executive of Texas A&M Health Science Center, site of one of the facilities. "We are prepared."

Global health agencies are only starting to consider whether to make experimental drugs, most of which have only been tested on monkeys, available to patients in West Africa, which is suffering the worst Ebola outbreak in history.

The World Health Organization is convening a group of bioethicists to consider such as issues as who decides which patients would receive the treatments or vaccines. US officials have repeatedly emphasized the importance of public health measures such as quarantines to stop the spread of the disease.

Among the Ebola treatments that have shown promising results in lab animals is an antibody cocktail from Mapp Biopharmaceutical, a tiny biotechnology company in San Diego; a vaccine from Profectus in Tarrytown, New York; and an RNA-interference drug being developed by Vancouver-based, Tekmira Pharmaceuticals, which late last week got approval from the U.S. Food and Drug Administration to resume safety trials in human volunteers.

The decision to order any of the three advanced labs to begin making Ebola treatments would be made at the highest levels of the Obama administration.

Bus-length clean rooms

The Texas facility consists of a dozen bus-length mobile clean rooms, each supplied with sterile air, nutrient media for growing cells, and other clean-manufacturing requirements.

"We are prepared to make any kind of vaccine," Giroir said, from the traditional kind grown in chicken eggs to newer varieties grown in mammalian or bacterial cells. "The whole idea is to take a process that may exist only on sticky notes at a small biotech company and scale it up as fast as possible"

The three centers are required to have the ability to produce vaccines against pandemic flu but must also dedicate at least six months a year to developing products against other threats, and at sufficient volume to meet a sudden spike in US demand, Giroir said.

The Texas facility collaborates with British drugmaker GlaxoSmithKline Plc. A center led by Emergent Biosolutions in Baltimore, Maryland, collaborates with various universities as does the third center, in Holly Springs, North Carolina, led by Swiss drug company Novartis AG.

Their operations are funded with $400 million from HHS and are overseen by the Biomedical Advanced Research and Development Authority (BARDA), part of HHS's Office of the Assistant Secretary for Preparedness and Response.

Combined, the centers have the capacity to produce and deliver at least 50 million doses of vaccine against pandemic influenza, the most likely source of a health emergency, within 12 weeks.

Any Ebola order would be for much fewer doses, said Giroir. "Even if Ebola were spreading here, it's not an airborne transmissible disease like influenza so you wouldn't need 50 million doses. At most you'd need a few thousand, maybe a million."

Scaling up

The centers are not set up to invent drugs. They are designed to take what Giroir calls "the scientific substrate" or recipe for the product, either an existing one or, as in the case of Ebola treatments, an experimental one and develop a process for making it.

Of the three, only the Texas lab said it can produce proteins such as human antibodies in plant-based systems, which is how Mapp's Ebola drug has been made in limited quantities, so the government may sub-contract with a company that has additional plant technology.

One candidate is Bryan, Texas-based Caliber Biotherapeutics LLC. Mapp currently works with Kentucky BioProcessing, a unit of tobacco giant Reynolds American to produce its drug. More capacity would be needed to scale up.

Emergent Biosolutions' facility does not have the recipe to develop an Ebola treatment, but Adam Havey, president of the company's biodefense division, said that if the government asked it to produce something against the virus "we would absolutely respond to that."

Novartis said its facility also "stands ready, as with previous public health emergencies, to provide scientific support aimed at halting the current outbreak."

Even with dedicated facilities to hand, getting medicines to Africa quickly and in sufficient quantities will be a challenge.

BARDA does have a network of distributors, including Baxter International Inc, Cook Pharmica LLC and JHP Pharmaceuticals, who would be obliged, if requested, to fill vials and package a BARDA-designated product.

While US legislation intended such production to be for U.S. use, there are provisions for products to be provided to allies and other countries if it is in the interest of national security.

Comments

0 comment