views

Obtain an emery board. Most of us have one of these sitting about in the bathroom cabinet. A finer-grit one is much better than a coarser-grit one for this purpose, since it will leave a smoother sharpened metal surface at the point of the needle, which is highly desirable. A very-fine-grit-diamond or very-fine-grit-stone tool/knife sharpener or scrap of very-fine-grit emery paper may have a finer grit than a fingernail emery board, and may leave a smoother point on the needle after grinding, which is highly desirable for this first step in repairing any kind of blunt needle. It is highly-desirable to create an extremely-smooth final metal surface everywhere on the needle.

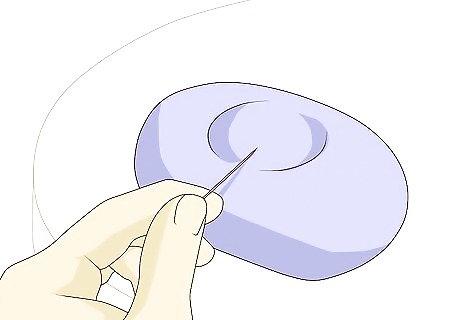

Test the sharpness of the needle's point against your skin. If the point is still as sharp as it can be, then the needle may only need to be polished to improve its performance. The needle's surface might be microscopically or visibly rough because of old scratches or corrosion, making the point falsely appear to be blunt. If the point is actually blunt, then rub the emery board around only the point area of the needle --- or pull the tip of the needle backward with some downward force (while turning the needle in your fingers) on the flat very-fine-grit sharpening surface at a shallow angle, as when sharpening a knife on a flat stone. This should sharpen the needle point. Be careful to grind only the area at the point. Be careful to not scratch the manufacturer's mirror-smooth finish anywhere else on the needle. Any scratches on the needle will need to be removed later by polishing, so don't add unnecessary scratches by grinding.

Polish the metal to make it as mirror-smooth as possible after grinding. Put a dab of toothpaste (that contains polishing grit) or automobile-paint-polishing paste or metal-polishing paste on a scrap of cloth lying on top of a rubber glove (as an impermeable pad) at the extreme edge of a kitchen or bathroom countertop. Pull the needle backward on the cloth repeatedly a large number of times, with some downward force, while turning it in your fingers to polish all sides of the needle. The gritty toothpaste or other gritty polishing paste on the cloth will become increasingly blackened, indicating that the metal is being microscopically polished. Eventually, the metal will become mirror-smooth. This is a long-proven, successful final procedure that is well-worth the effort. You can also polish the entire needle in this way, which is well-worth the effort. A sewing-machine needle, for example, absolutely must have a manufacturer's mirror finish if it is to work well in the machine. Clean the polishing paste off the polished needle and off your fingers using detergent or soap, and water.

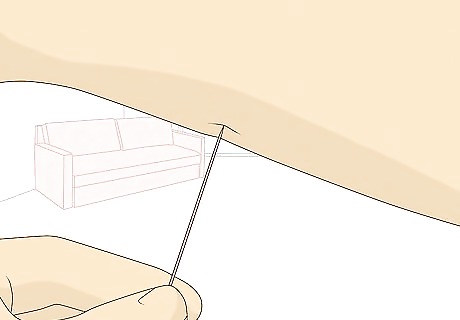

Use soap. If you are still experiencing difficulties in pushing through the needle after using the emery board (only if necessary) --- or other very-fine-grit grinding surface (only if necessary) --- followed by the important final polishing-paste procedure to achieve a manufacturer's mirror-like surface, then you can rub the needle (entire length) across a bar of dry soap. As you continue to work with your fabric, stick the needle point into the bar of soap occasionally to continue giving it a smooth surface. The soap does not damage the fabric.

Comments

0 comment