views

Cleaning Up the Damaged Spot

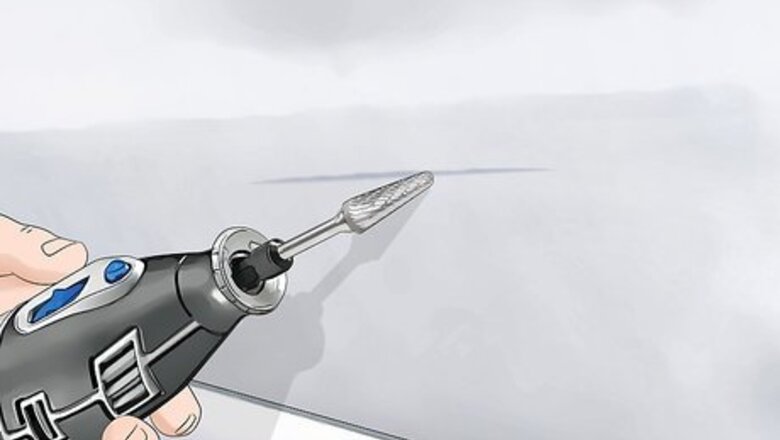

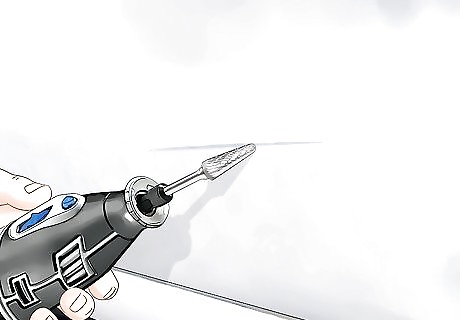

Use a rotary tool with a burr bit to taper the edges of gouges. Attach a V-shaped burr bit to a rotary tool such as a Dremel tool. Turn it on and hold the tip against one side of the gouge at a 45-degree angle. Move it back and forth along the sharp edge of the gouge, applying light pressure, to smooth it out. Repeat this for the other side to create a U-shaped groove.Warning: Wear safety glasses when operating a rotary tool so you don’t get any dust in your eyes. A Dremel tool is a rotary tool that you can attach all kinds of bits to for things like sanding, grinding, and polishing. A burr bit is a type of bit that comes in various cone shapes and can be used for sanding and grinding. You can get both things at a home improvement store or order them online. Use this method for deep gouges or chips that have sharp edges. You just want to remove the sharp edges of the gouge so the new gelcoat will blend in with the surrounding gelcoat better.

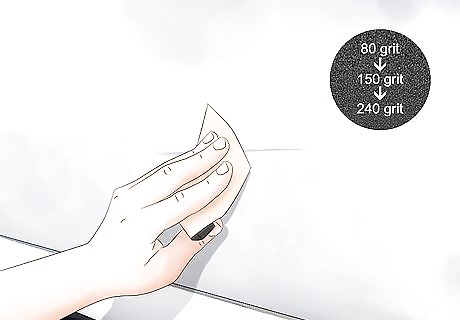

Sand out small scratches with 80-grit, 150-grit, and 240-grit sandpaper. Sand with the direction of fine scratches starting with 80-grit sandpaper until the scratch is even with the area around it. Switch to 150-grit sandpaper and sand until the scratched area is evenly smooth, then switch to 240-grit sandpaper and sand it until the texture becomes even smoother and the damage is blended in to the area around it. You can use this method for very thin scratches that don’t have sharp edges.

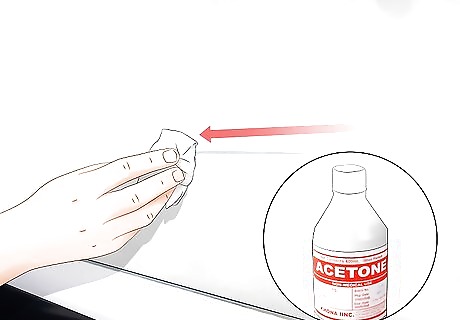

Wipe the surface of the damaged area with acetone to clean it. Pour a bit of acetone onto a clean cloth. Wipe over the area you will repair to remove dirt, dust, and any other surface residues. If there is a lot of dust from sanding and grinding, you can also use a vacuum with a hose attachment to suck it up.

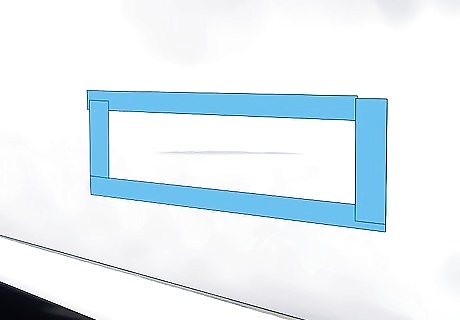

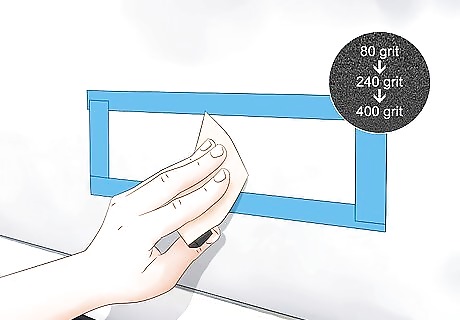

Tape all the way around the damaged area with painter’s tape. Use 2 in (5.1 cm) wide blue painter’s tape. Box off the damaged area, leaving about ⁄16 in (0.16 cm) of space around the damage. If you are working in an area where the new gelcoat could drip down, then mask off the area below it with tape as well to protect it. You can tape plastic sheets over large areas to protect them.

Applying and Finishing New Gelcoat

Purchase a wax gelcoat repair kit that matches the color of the damaged spot. Gelcoat repair kits come with 2 parts that you mix together right before applying it to the damaged area. Try to match the color as closely as possible or get a kit that has different pigments you can add while mixing to change the color. Gelcoat repair kits are available at marine supply shops, home improvement centers, paint supply stores, and online. A marine supply shop may be able to provide you with an exact match for your model and color of boat if it is a current model. Wax gelcoat is the best option to repair gelcoat because it will cure in the air without any additional components needed.

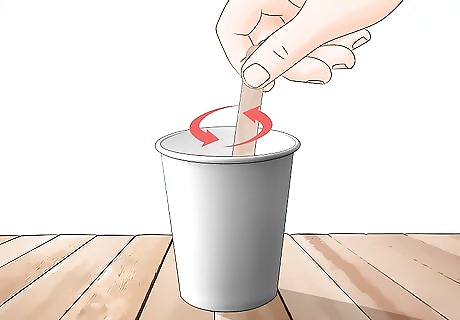

Mix the new gelcoat according to the manufacturer’s instructions. Pour the amounts of each part recommended by the manufacturer into a plastic or paper disposable cup. Stir it with a mixing stick for at least 1 full minute or until it is about the consistency of peanut butter.Warning: Make sure you mix enough of the gelcoat to repair the entire damaged area at once. If not, it may not all cure at the same rate. Wear gloves, safety glasses, and a face mask when you mix the gelcoat. If your gelcoat repair kit doesn’t come with a mixing stick, then use a clean craft stick (like a wooden popsicle stick) to mix the gelcoat. Different gelcoat repair kits require you to add different amounts of hardener, also known as catalyst, to the gelcoat mixture so that it cures properly. Make sure you use the exact ratios or your gelcoat will either dry too quickly or won’t cure all the way.

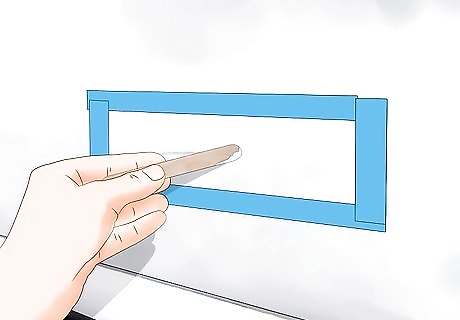

Press the gelcoat onto the damaged area with the mixing stick. Scoop enough of the putty out to overfill the damaged area by about ⁄32 in (0.079 cm). Tap it with the tip of the mixing stick so it gets into the fibers and spread it out at the sides so it blends in with the surrounding area. If you are repairing an area where you sanded out light scratches, then just rub an approximately ⁄32 in (0.079 cm) layer of the putty over the sanded area with the mixing stick. You will have about 10-15 minutes to work before the gelcoat starts to harden.

Let the gelcoat dry for at least 8 hours to cure. Leave the repaired area to dry overnight or for at least 8 hours. This will ensure that the gelcoat is hard enough for sanding and finishing. Touch the gelcoat to make sure it is hard before you proceed to sand it. If it still feels sticky or tacky, then let it dry longer until it is hard.

Sand down the repaired area with 80-grit, 240-grit, and 400-grit sandpaper. Use a sanding block and sand in circular motions. Start with 80-grit sandpaper and sand until the repaired area is level with the surrounding area. Move on to 240-grit sandpaper and sand until it is completely smooth, then switch to 400-grit sandpaper to smooth it out even more so it feels like the surrounding areas. If the area still feels rough after you use 400-grit sandpaper, you can keep working your way up all the way to about 1000-grit sandpaper until you are happy with the smoothness.

Buff the repaired area with an electric buffer and rubbing compound. Apply rubbing compound directly to the pad of an electric buffer and turn it on to low speed. Buff over the repaired area with medium pressure and stop when the rubbing compound starts to dry. Remove the tape from around the repaired area before you begin buffing. Wipe away the haze from the rubbing compound with a clean cloth as you go.

Apply a coat of wax to the buffed area to finish. Use whatever wax you would normally use for your boat and apply it the same way you applied the rubbing compound with the electric buffer. Finish it off with a quick hand buff by rubbing a clean cloth in circular motions until there is no more haze and it looks shiny. Once the wax has dried, after about 15 minutes in the sun, you can wash your whole boat and give the whole thing a second coat of wax so that the repaired area and the rest of the boat are equally shiny.

Comments

0 comment